- All material contacting parts of stainless steel

- Big material passages

- Easy maintenance and repair

- Fixed mixing ratio 1 : 1 - continuously electronically monitored

- You can find more information on the application and process techniques with the DESOI w.i.l.m.a. in the STUVA ABI leaflet "Sealing of structures by injection", 4th edition - Part III/1.3.2 from p. 57.

- acrylate gel

| Working pressure - infinitely variable | 5 - 120 bar |

| Delivery rate | |

| - with air performance of 0,7 m³/min (2 x compressor V-Meko 400) | max. 10 l/min |

| - with air performance of 1.3 m³/min | max. 13 l/min |

| Air consumption | min. 0.5 m³/min |

| Transmission ratio | 1:15 |

| Mixing ratio | 1:1 |

| Air pressure | max. 8 bar |

| Weight | 85 kg |

| L x W x H | 77 x 55 x 112 cm |

| Rinsing pump | |

| Working pressure - infinitely variable | 7 - 220 bar |

| Delivery rate | 5 l/min |

| Transmission ratio | 1:27,5 |

| Control cabinet | |

| Supply voltage (adjustable ex works) | 110 - 230 V/0,5 Ampere |

| Storage type | digitally on tablet |

| Data transfer | WLAN |

| Measuring range - volume (depending on the sensor) | 100 l/min. |

| Measuring range - pressure (depending on the sensor) | max. 250 bar* |

| Measurement accuracy | ± 2 % v ME |

| Weight | 8.62 kg |

| L x W x H | 30 x 19 x 33 cm |

| *1 bar = 105 Pa. (Pascal) | |

| Tablet | |

| Storage type | digitally on tablet |

| Hard disk space | 64 GB |

| Data transfer | WLAN |

| Weight - tablet | 1,26 kg |

| L x W x H - tablet | 28 x 19 x 3,5 cm |

The combination DESOI w.i.l.m.a. and DESOI AirPower M35-3C VA is ideal for injection work with acrylic gel. The piston pump achieves a delivery rate of max. 13 l/min at a mixing ratio of 1:1 and is equipped with a separate rinsing pump. The sealing sets inside are protected by an integrated spring pre-tensioned, manual re-tensioning is not necessary. DESOI w.i.l.m.a. monitors and documents the material consumption, the injection pressure and the mixing ratio.

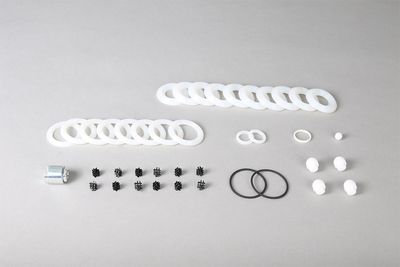

Accessories

You can also rent this device flexible.

You can also rent this device flexible.